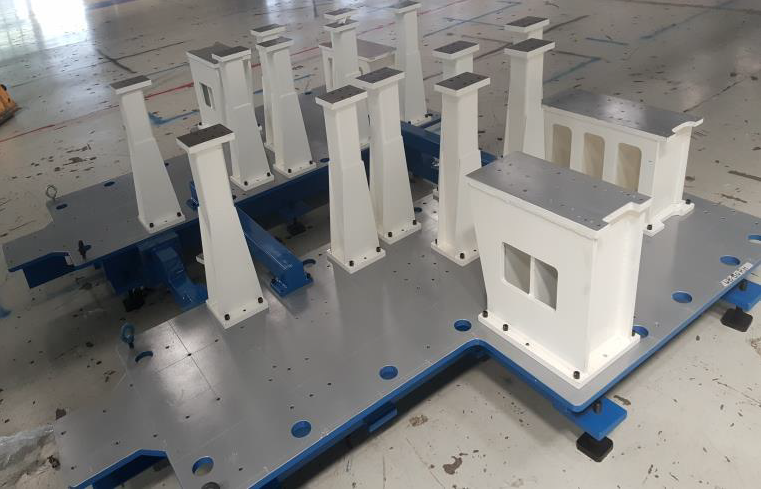

Advanced engineering tools are utilized in development of each machine part, accompanied by required quality checks are performed at each stage of production. Due to the flexibility available with robotic systems, integration in a variety of areas is made possible. Areas include virtually every industry and robotic application including material handling, welding, precision part handling, etc.

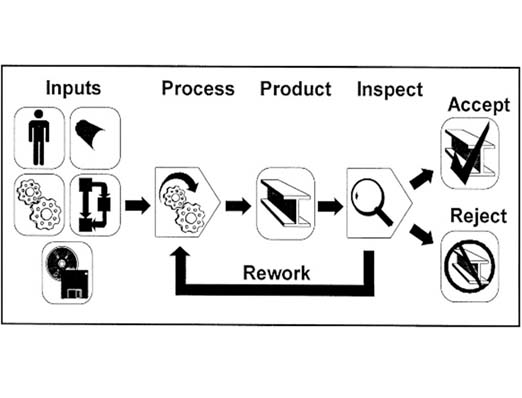

We as an organization believe in delivering quality Products & Services to our Clients and in order to do so quality should be checked and maintained at every stage of the organization structure. To manufacture high-quality products or parts, regular quality control is essential to ensure that production parameters are within specified limits. If checked too late in the process, an entire lot could fail to meet the specification.

Product Inspections allow you to verify product quality on site at different stages of the production process and prior to its dispatch. Inspecting your product before it leaves the manufacturer’s premises is an effective way of preventing quality problems and supply chain disruptions further down the line.